Packaging

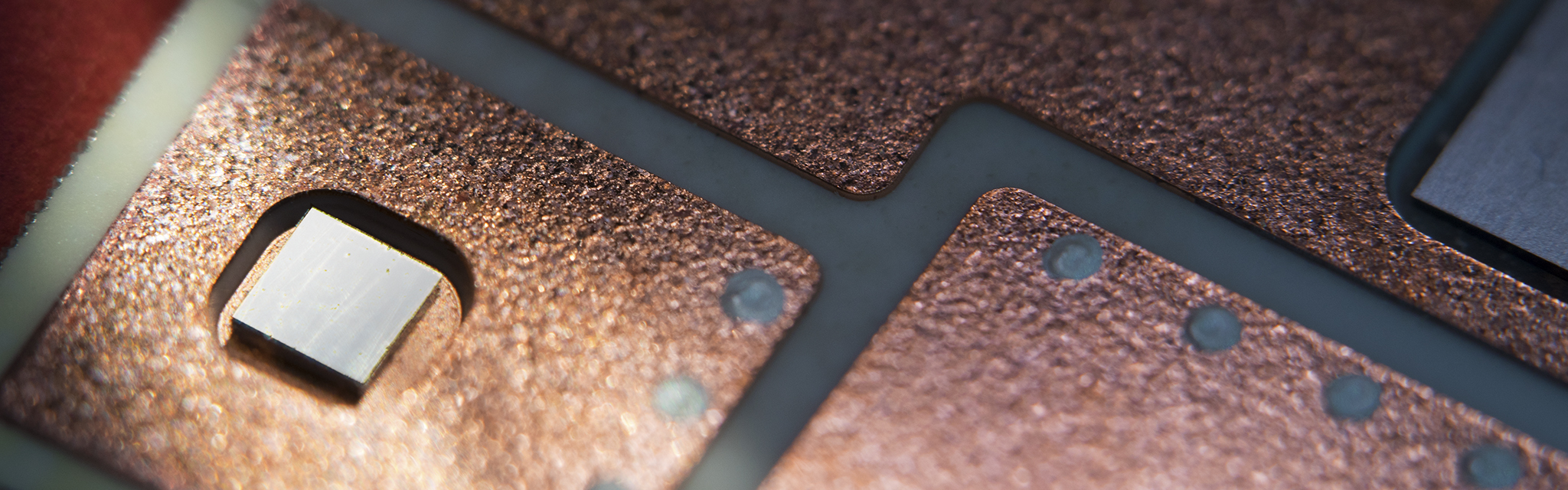

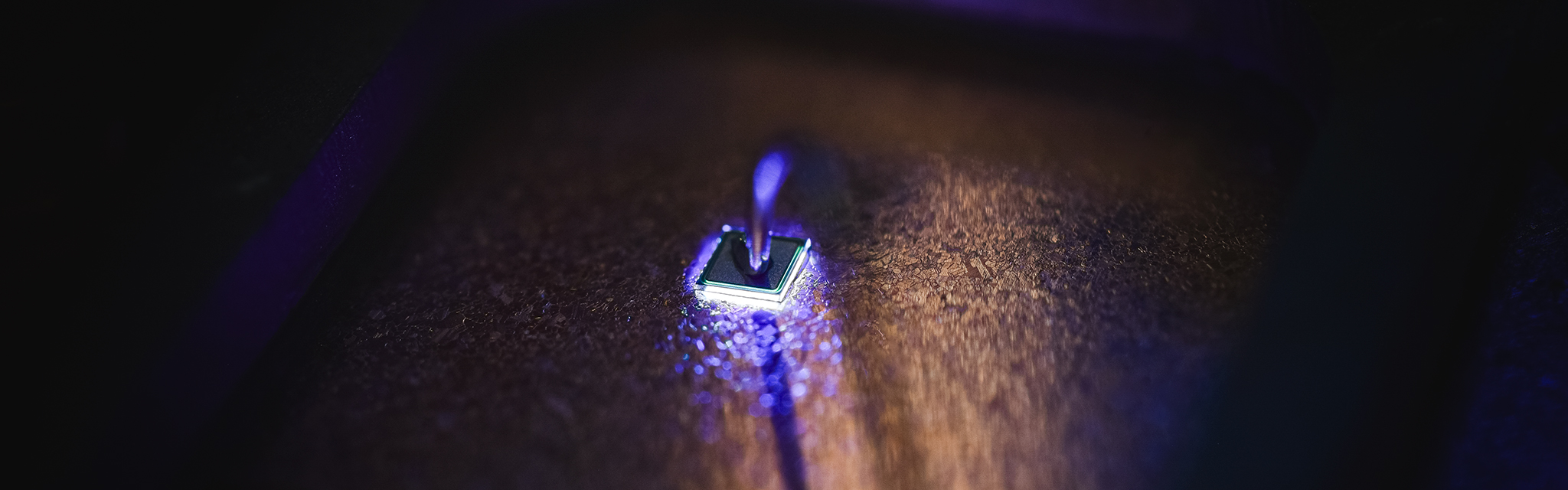

The research field is packaging of power electronics. The drivers are performance, volume and weight per cost depending on the application. The goal is reached by investigations of different concepts of the electrical, mechanical and thermal design such as single and double sided die attach, single and double sided cooling, materials with minimized or matched coefficient of thermal expansion (CTE). By use of intelligent setups and application relevant measures of the electrical and thermal interconnections the bill of material is minimized.

Work is done on joining technologies as well. There is a long experience in silver sintering as an alternative to the state of the art. Meanwhile a process is established to manufacture multichip power modules with high yield. Especially a selective sintering process brings big pace to electronic packaging, especially on printed circuit board. The chips sizes meet the power electronics requirements. While the sintering improvements are ongoing the soldering technology is still covered for new high performance or high temperature materials.

Fraunhofer Institute for Integrated Systems and Device Technology IISB

Fraunhofer Institute for Integrated Systems and Device Technology IISB