The FMD is a global innovation driver which, as the largest multi-site R&D consortium for microelectronics in Europe, offers a unique diversity of competencies and infrastructure. FMD bridges the gap between basic research and customer-specific product development. In the field of power electronics, FMD's range of services includes the manufacture of power electronic devices and their integration into modules and systems. Special attention is paid to the manufacture and processing of Wide-Band-Gap (WBG) semiconductors, i.e. semiconductor materials with large band gaps (SiC, GaN, AlN, Diamond).

Within FMD, Fraunhofer IISB has a unique selling point with its integrated production line for the processing of individual SiC-based prototype devices in an industry-compliant environment.

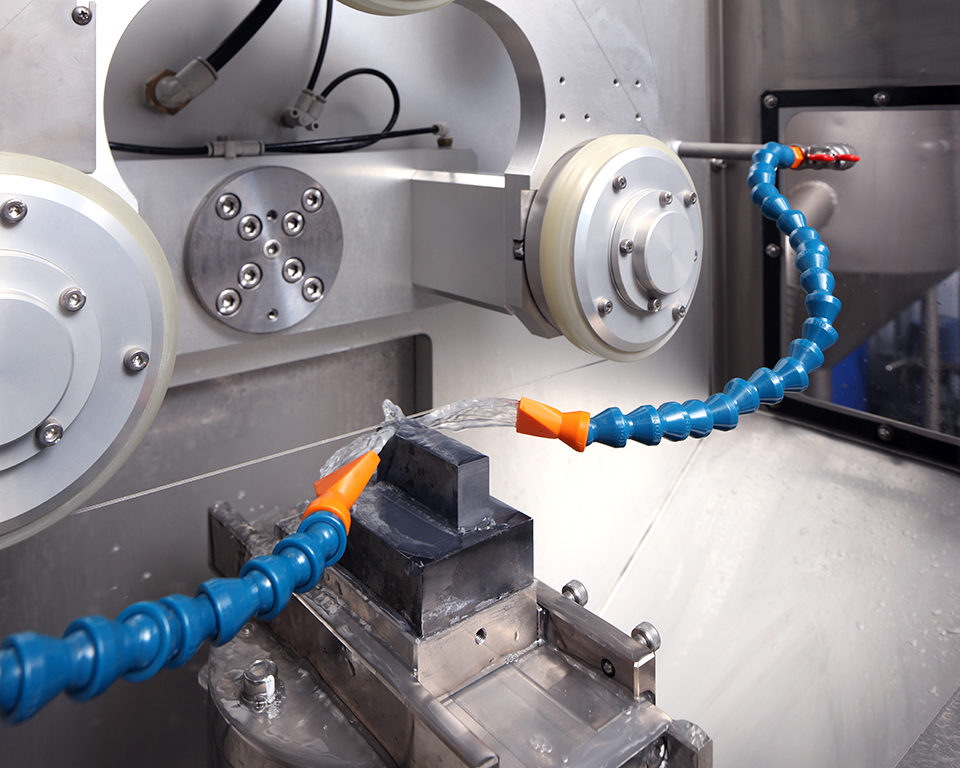

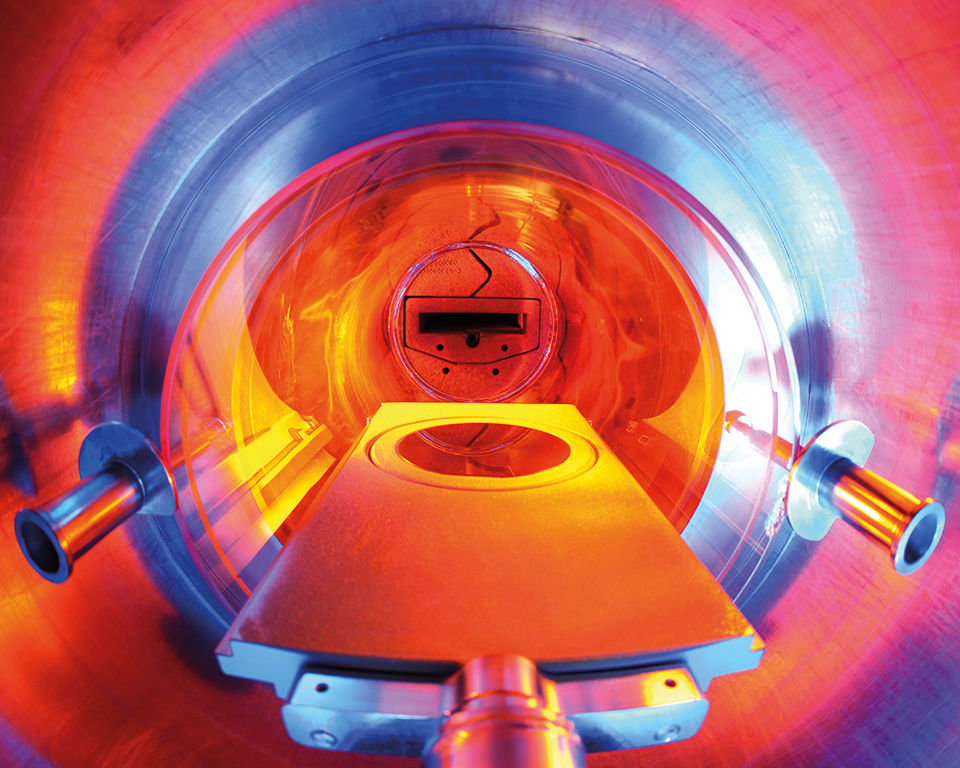

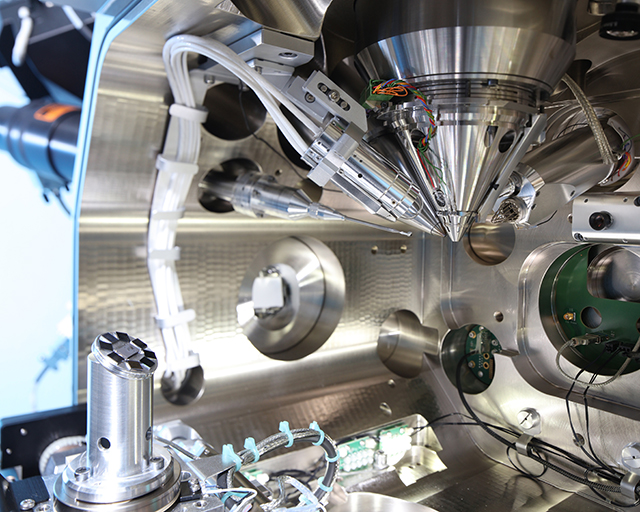

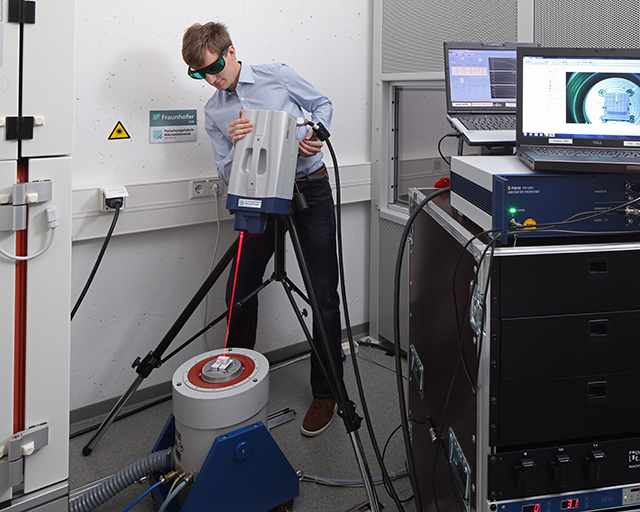

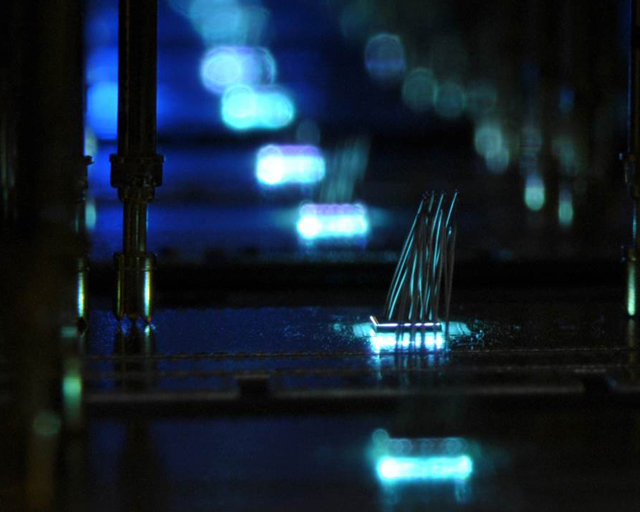

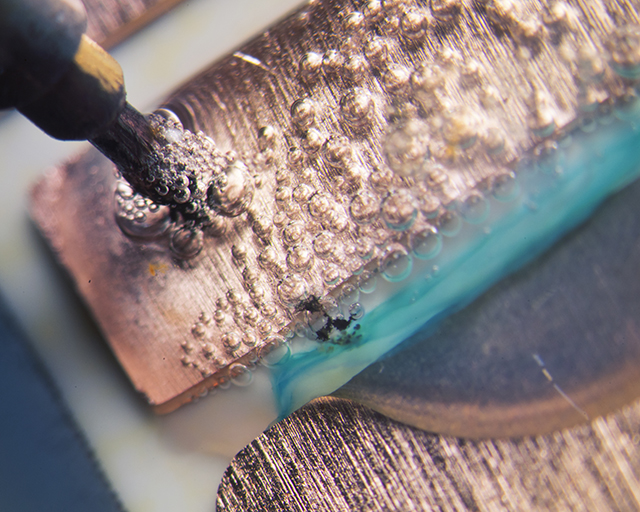

In the front-end area for wafer sizes of 100 mm and 150 mm, all desired process steps can be performed at Fraunhofer IISB, such as epitaxy, ICP dry etching, growth of silicon dioxide, aluminum implantation at elevated temperatures, activation tempering or conductive contact alloy. Usually, vertical components are manufactured in SiC for power electronics. Therefore, the processing of the backside of the SiC wafers is of critical importance. The FMD investments now also enable the bonding and debonding of already processed wafers, the thin grinding of wafers and the reduction of contact on the rear side by means of advanced metallization and laser silicidation.

New integration technologies and innovative assembly and system concepts for prototyping and the production of future power modules are available in the backend area. This makes it possible, for example, to realize particularly complex and compact structures, heavily stressed (special) applications with sometimes small quantities or durable high-temperature power electronic modules.

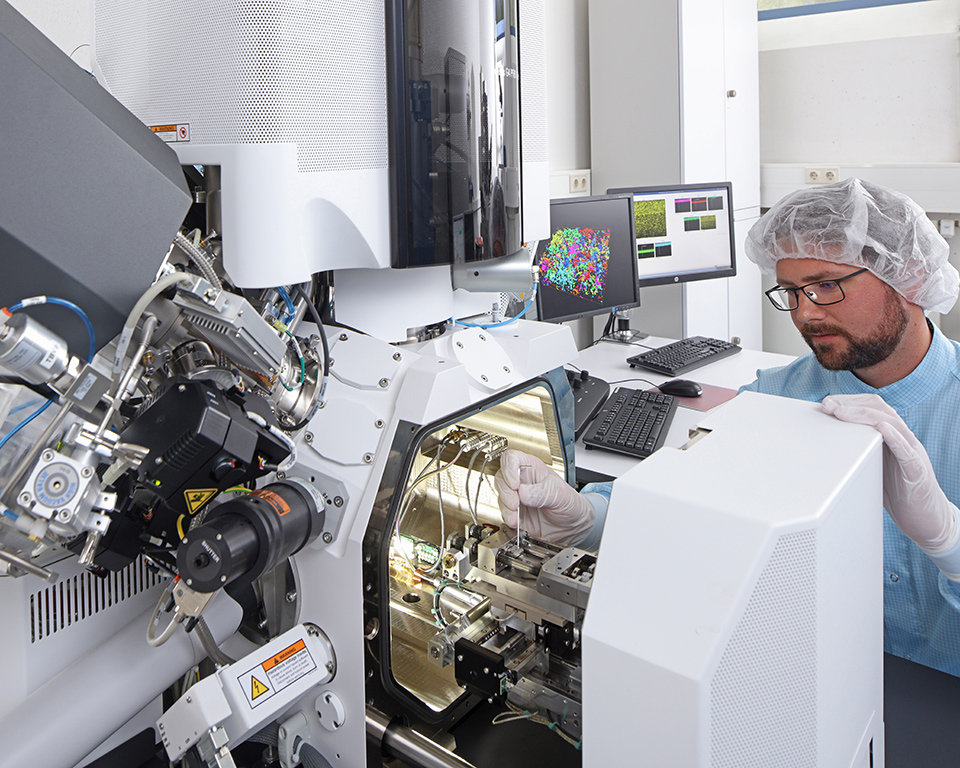

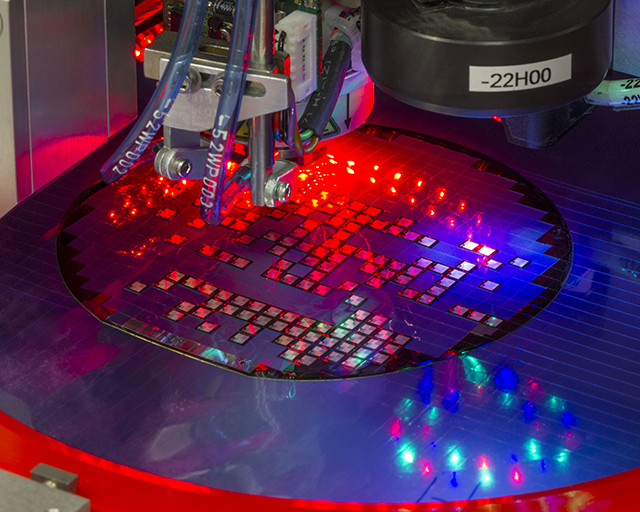

Extensive, complementary methods are available along the process chain for quality control. The most important of these are a fast, high-resolution X-ray topography system for the analysis of the structural properties of crystals, wafers and partially processed wafers and a combined surface inspection photoluminescence device for the analysis of the near-surface material properties of SiC along the process chain. The equipment is supplemented by special measuring stations, which are adapted to the specific, sometimes extreme conditions of power electronics, such as an extra-high voltage measuring station as well as special lifetime and reliability test laboratories.

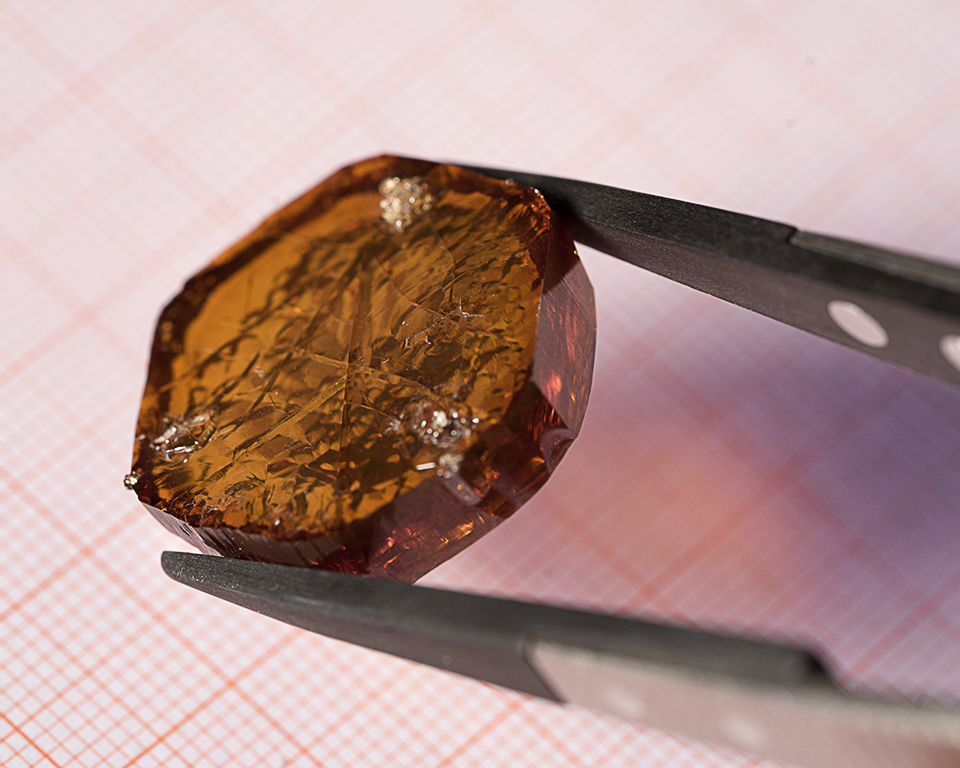

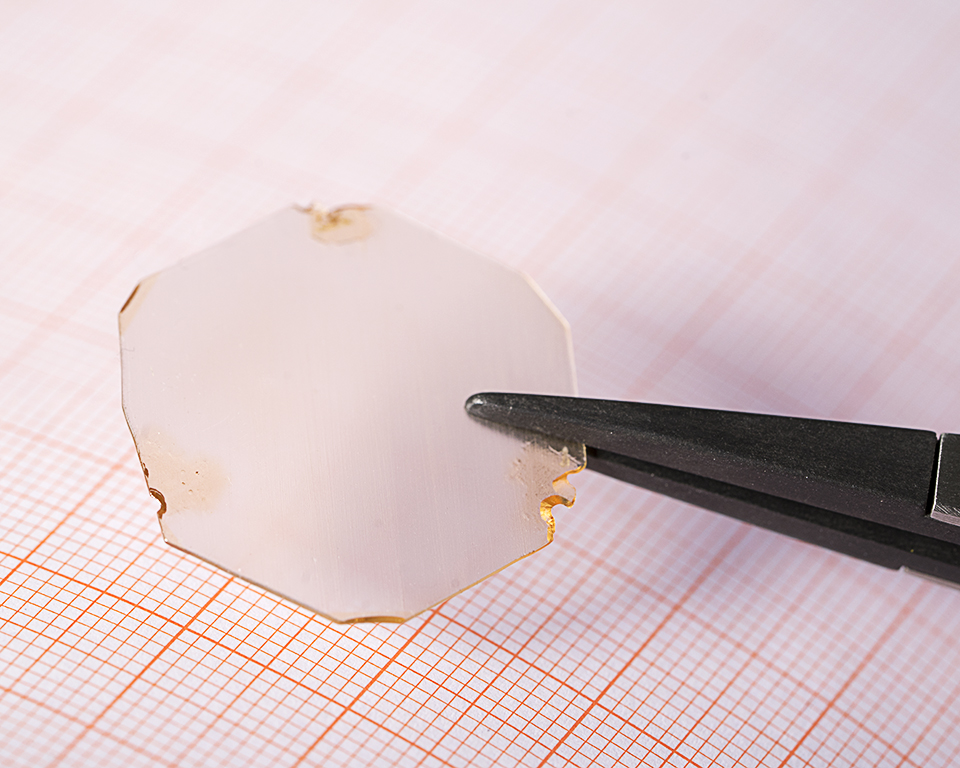

For the research of new semiconductor materials with large band gaps, crystals of these materials are needed, which then have to be further processed into wafers in order to evaluate the potential in FMD for power electronics or for other applications such as in quantum technology. Since the new crystal materials, such as GaN, AlN or Diamond, are usually crystals with small diameters (50 mm or smaller), Fraunhofer IISB operates a special substrate and wafer laboratory to produce wafers from such crystals. The quality of the wafers used to manufacture the devices is tested using various analytical methods, including the determination of their epitaxial suitability and the production of special test structures.

Fraunhofer Institute for Integrated Systems and Device Technology IISB

Fraunhofer Institute for Integrated Systems and Device Technology IISB